Revolutionizing Production: The Transformative Role of Technology in the Manufacturing Industry

In the modern era, technology is the driving force behind innovation, efficiency, and growth in the manufacturing sector. From automation and artificial intelligence to advanced robotics and data analytics, technology has transformed the way products are designed, produced, and delivered. This article explores the pivotal role of technology in the manufacturing industry, highlighting its impact on processes, products, and overall economic development.

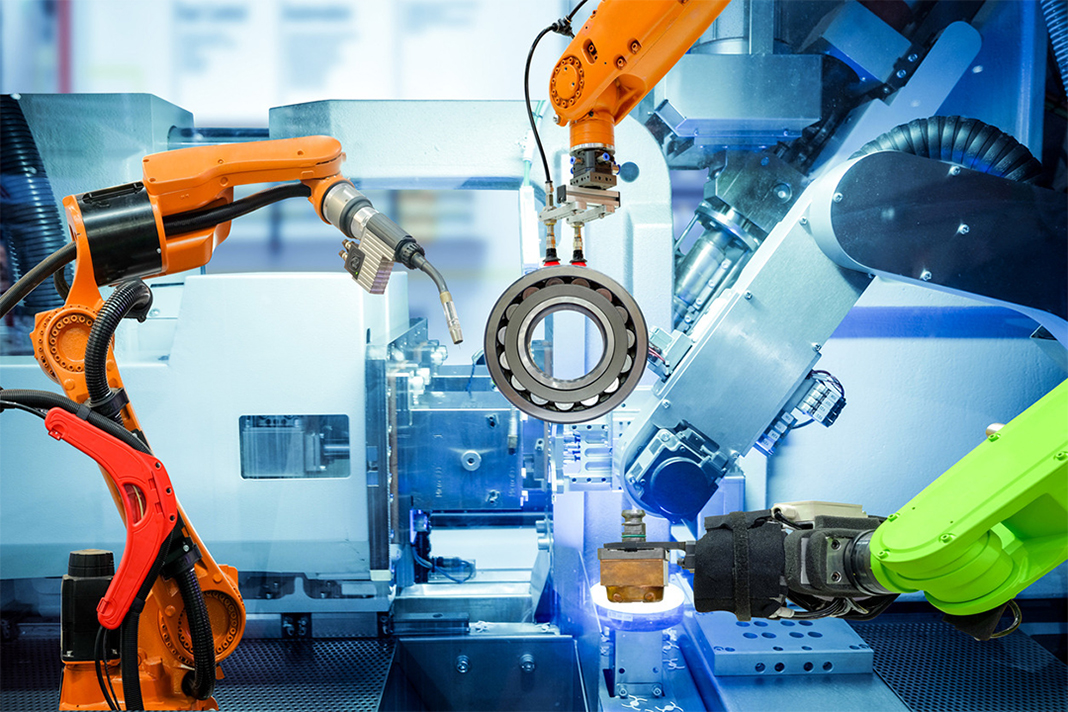

1. Automation and Robotics:

Automation technology, including robotics and computer numerical control (CNC) systems, has revolutionized manufacturing processes. Robots are capable of performing repetitive tasks with unmatched precision and speed, leading to increased production rates and reduced errors. Automation not only enhances efficiency but also ensures worker safety by handling hazardous tasks, creating a safer working environment.

2. Internet of Things (IoT) and Connectivity:

The Internet of Things (IoT) has enabled seamless connectivity between machines and systems on the manufacturing floor. IoT sensors collect real-time data, providing insights into equipment performance, production efficiency, and supply chain management. This data-driven approach allows manufacturers to optimize operations, predict maintenance needs, and make informed decisions, enhancing overall productivity.

3. Advanced Data Analytics and Artificial Intelligence:

Data analytics and artificial intelligence (AI) algorithms process vast amounts of data to extract valuable insights. Predictive analytics help manufacturers forecast demand, optimize inventory levels, and improve supply chain management. AI-driven algorithms enhance quality control, detect defects, and optimize production parameters, ensuring products meet high standards while minimizing waste.

4. 3D Printing and Additive Manufacturing:

3D printing, also known as additive manufacturing, has revolutionized prototyping and production processes. This technology allows manufacturers to create complex components layer by layer, reducing material waste and production time. 3D printing enables rapid prototyping, customization, and the production of intricate designs, opening up new possibilities for product development.

5. Smart Factories and Digital Twins:

Smart factories integrate technologies such as IoT, AI, and automation to create interconnected and intelligent manufacturing systems. Digital twins, virtual replicas of physical products and production processes, allow manufacturers to simulate and optimize production in a virtual environment. This simulation-driven approach enhances efficiency, reduces downtime, and accelerates innovation.

6. Supply Chain Optimization:

Technology plays a crucial role in optimizing supply chain management. Advanced software solutions track inventory levels, monitor supplier performance, and optimize logistics and distribution. Blockchain technology ensures transparency and traceability in the supply chain, reducing the risk of counterfeit products and improving overall efficiency in the manufacturing ecosystem.

7. Customization and Flexible Manufacturing:

Technological advancements enable mass customization in manufacturing. Flexible automation systems and digital control mechanisms allow rapid reconfiguration of production lines to accommodate diverse product variants. This flexibility meets the growing demand for personalized products, enhancing customer satisfaction and market competitiveness.

In conclusion, technology is reshaping the manufacturing industry, driving innovation, efficiency, and competitiveness. Manufacturers embracing these technological advancements are not only improving their operational efficiency but also fostering a culture of innovation and adaptability. As technology continues to evolve, the manufacturing industry stands at the forefront of this digital revolution, creating a future where products are not only made with precision but also with unprecedented levels of customization and sustainability.

Leave a Reply